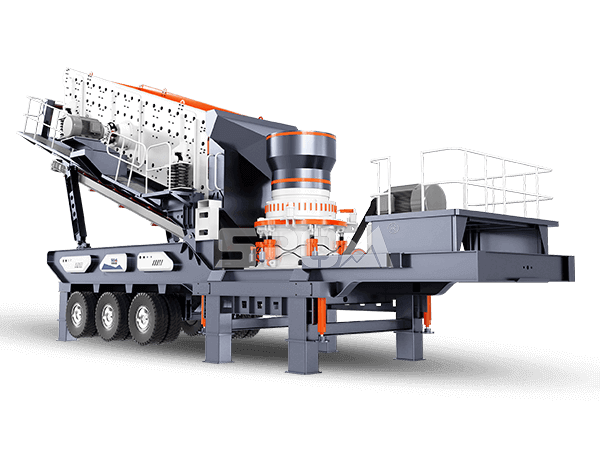

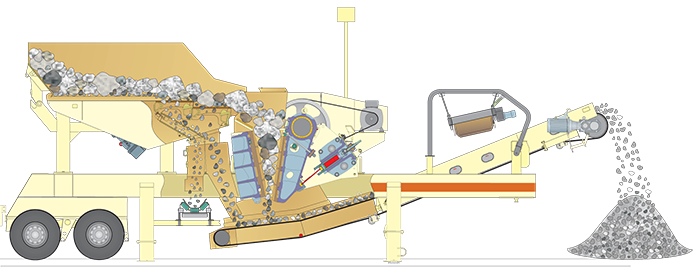

Tire-type mobile crushing plant is a new type of mobile crushing equipment, which can supply the customers the best crushing and screening solutions. Considering from the customers’ standpoint, efficiently integrates the feeding equipment, crushing equipment, screening equipment, effectively solving the site constraints of the fixed crushing plants. It not only avoids the site infrastructure, but also expands the material stack space due to the compact equipment layout. Mobile crushing plant has the obvious advantages of crushing while moving, winning more and more customers’ recognition, Mobile crushing plant is divided into mobile jaw crusher plant, mobile impact crusher plant, mobile cone crusher plant, which is widely used in the road and bridge construction, urban construction, metallurgy, energy, and other crushing and screening industries.

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

Language

Language

Email:sales@shibochina.com

Email:sales@shibochina.com

Chat Online

Chat Online Get Quote

Get Quote