20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

High efficiency and better quality

High efficiency and better quality

Provid a spring type protection device

Provid a spring type protection device

Reasonable structual and easy to adjust

Reasonable structual and easy to adjust

Easy adjust the particle size of crushing and discharging

Easy adjust the particle size of crushing and discharging

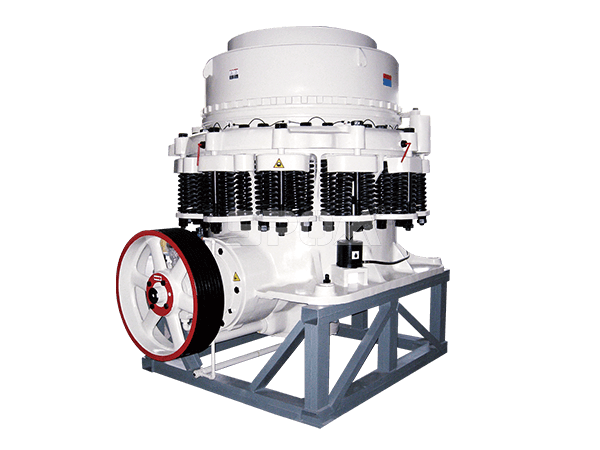

Cone crusher crushes materials by the working surface between the movable cone and fixed cone. So it is more advanced and efficient than jaw crusher. The movable cone is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and fimbriated gear, and the wheel of the conveyor belt is driven by motor through v-belts. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks are grinded into pieces, when the movable cone leaves, grinded materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size is determined adjusted.

| Model | Feeding size(mm) | Capacity(t/h) |

| PYB600 | ≤ 75 | 15-25 |

| PYD600 | ≤ 35 | 5-23 |

| PYB900 | ≤ 115 | 50-90 |

| PYZ900 | ≤ 60 | 20-65 |

| PYD900 | ≤ 50 | 15-50 |

| PYB1200 | ≤ 145 | 110-168 |

| PYZ1200 | ≤ 100 | 42-135 |

| PYD1200 | ≤ 50 | 18-105 |

| PYB1750 | ≤ 215 | 280-480 |

| PYZ1750 | ≤ 185 | 115-320 |

| PYD1750 | ≤ 85 | 75-230 |

| PYB2200 | ≤ 300 | 490-750 |

| PYZ2200 | ≤ 230 | 200-580 |

| PYD2200 | ≤ 100 | 120-340 |

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Price

Get Price