20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

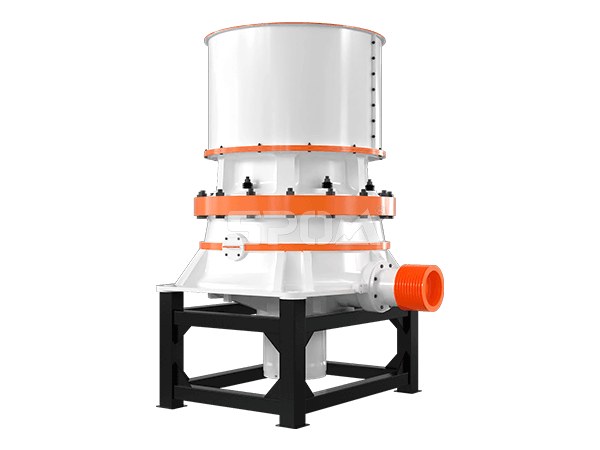

Simple structure and strong reliability

Simple structure and strong reliability

Large production capacity and high crushing efficiency

Large production capacity and high crushing efficiency

Rolling mortar wall does not need filler, replacement is quick and convenient

Rolling mortar wall does not need filler, replacement is quick and convenient

Automatic control system, material blocking alarm function

Automatic control system, material blocking alarm function

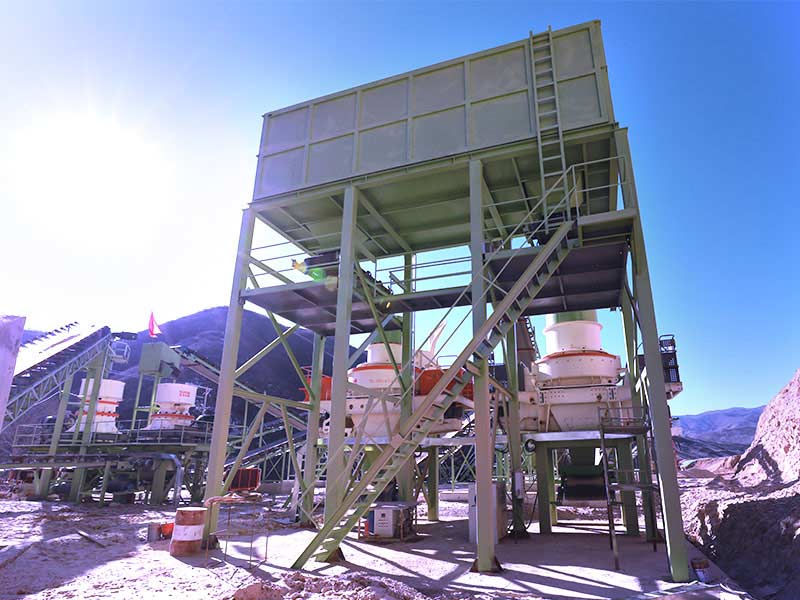

The electromotor leads the eccentric sleeve to rotate by the V-belt, drive shaft and drive gear. The movable cone does rotary and pendulum movement under the leading role of eccentric sleeve which makes the movable cone and fixed cone close and far away from time to time. The raw material is crushed in the crusher chamber by squeezing and striking continuously. The crushed stone discharges from the bottom.

| Model | Maximum feed inlet Size (mm) | Capacity (t/h) |

| SH420 | 38-240 | 27-170 |

| SH430 | 50-360 | 48-345 |

| SH440 | 70-450 | 90-605 |

| SH660 | 65-560 | 205-1050 |

| Fine | Fine(mm) |

| SH420 | 70-170 |

| SH430 | 90-345 |

| SH440 | 190-605 |

| SH660 | 305-1050 |

| Fine | Fine(mm) |

| SH420 | 27-130 |

| SH430 | 48-210 |

| SH440 | 90-390 |

| SH660 | 170-665 |

| SH870 | 280-1512 |

| SH870 | 280-1512 |

| SH890 | 364-2128 |

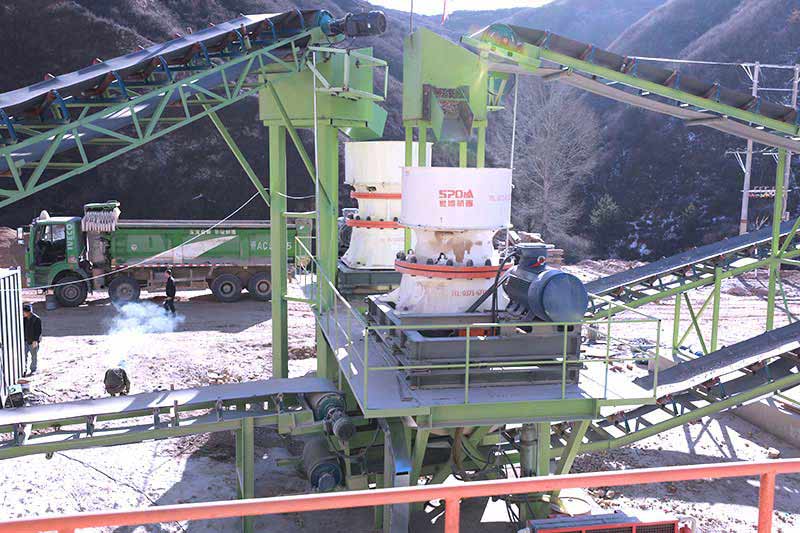

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Quote

Get Quote