20-30mm、10-20mm、5-10mm、0-5mm

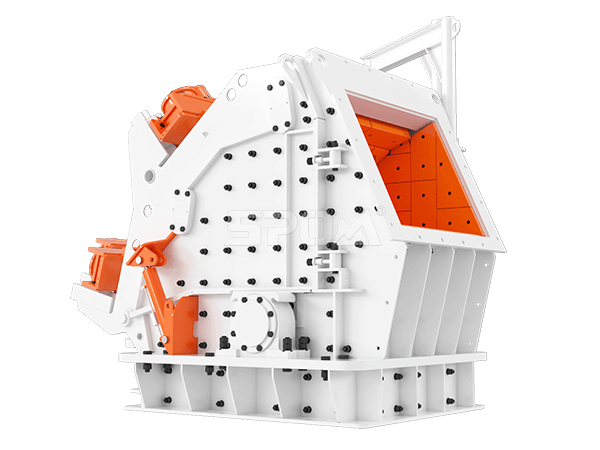

It can crush more than 100 kinds of rocks. The common discharge size is...

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

Coarse and medium crushing

Coarse and medium crushing

Large crushing ratio

Large crushing ratio

Wear-resistant, stable discharge particle size

Wear-resistant, stable discharge particle size

Easy to adjust and wide range

Easy to adjust and wide range

The material is evenly conveyed into the jaw crusher by the feeder, the material after primary crushing by the jaw crusher is sent to the impact crusher through the conveyor for secondary crushing, and the crushed material is screened by the vibrating screen to meet the crushing requirements. The required materials are output by the conveyor, and the materials that do not meet the requirements enter the impact crusher again for crushing. The entire production line of the crawler-type jaw crusher + impact crusher mobile station forms a closed-circuit system through a circular vibrating screen to realize the cyclic crushing of the materials, and the finished materials are conveyed by Machine output, continuous crushing operation.

| Model | Max Input Size(mm) | Capacity(t/h) |

| LF150 | ≤500 | 100-200 |

| LF250 | ≤700 | 200-400 |

| LF350 | ≤800 | 300-500 |

| LF450 | ≤900 | 350-580 |

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Quote

Get Quote