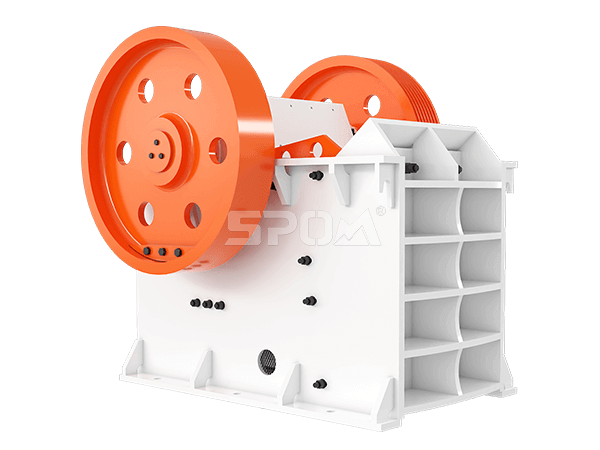

As an important equipment for coarse crushing in the crushing process, jaw crusher is one of our core products, and it is also a product with a long history in the company's production. Over the years, we have been focusing on the R&D and manufacturing of high-performance crushers, supported by several customers on site. The products have undergone several iterative upgrades, and the introduction of more advanced European technology has condensed the CJ series jaws that are currently at a high level in the market. crusher. CJ series jaw crusher adopts innovative modularized, non-welded structure frame, high-quality alloy steel castings and rolling bearings, which greatly improves the fatigue resistance and operational reliability of the equipment, and fully guarantees the high output, High efficiency and low cost, a variety of flexible installation methods to meet different application options.

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

Language

Language

Email:sales@shibochina.com

Email:sales@shibochina.com

Chat Online

Chat Online Get Quote

Get Quote