Production line is introduced: the iron ore crusher has been widely used in mining, metallurgy, chemical, building materials, roads, railways, water and other industries. the applied material consist of hematite, magnetite, siderite, limonite, etc.

Machinery Recommended: Jaw Crusher + Cs Series Cone Crusher + Cone Crusher + Magnetic Separator + Sand Screening Machine + Vibrating Feeder + Belt Conveyor

Iron ore is an important raw material of steel producers.After crushing, grinding, magnetic separation, flotation, re-election and other procedures,natural minerals(iron ore)elected gradually of iron. Iron exist in nature all in compounds state, especially in the state of iron oxide but has more impurities. Such as hematite, magnetite, siderite, limonite, etc.

IRON ORE CRUSHING & PROCESSING

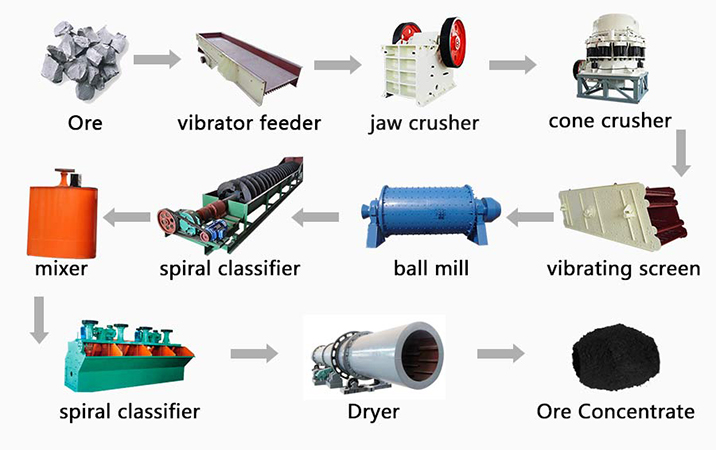

Large iron ore is sent to the jaw crusher or mobile jaw crusher for coarse crushing by the vibrating feeder. The coarsely-crushed iron ore is sieved by the vibrating screen and sent by the belt conveyor and secondary crushed by single-cylinder hydraulic cone crusher; the crushed iron ore material is fed into HP Series multi-cylinder hydraulic cone crusher for fine crushing;

The iron powder 0-12 mm sieved by the vibrating screen was evenly sent to the ball mill for milling, and was sieved by a spiral classifier. If it did not meet the requirements, it was sent to a ball mill to continue milling.

The iron powder that meets the ore dressing requirements is sent to the magnetic separator for magnetic separation.magnetic separation is used to remove impurities;

The iron powder obtained is sent to a dryer and dried to obtain iron powder.

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Price

Get Price