20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

Hydraulic Lubrication Combined Oil Station

Hydraulic Lubrication Combined Oil Station

The discharge port is adjusted by the hydraulic push cylinder, which is easy to adjust

The discharge port is adjusted by the hydraulic push cylinder, which is easy to adjust

Dust removal mechanism adopts dry oil seal

Dust removal mechanism adopts dry oil seal

Reliable structure and low failure rate

Reliable structure and low failure rate

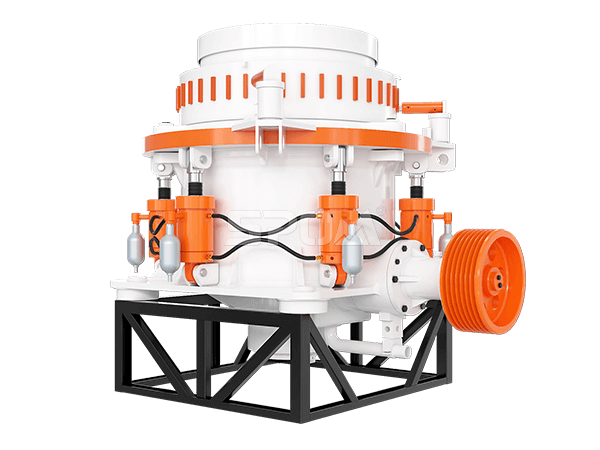

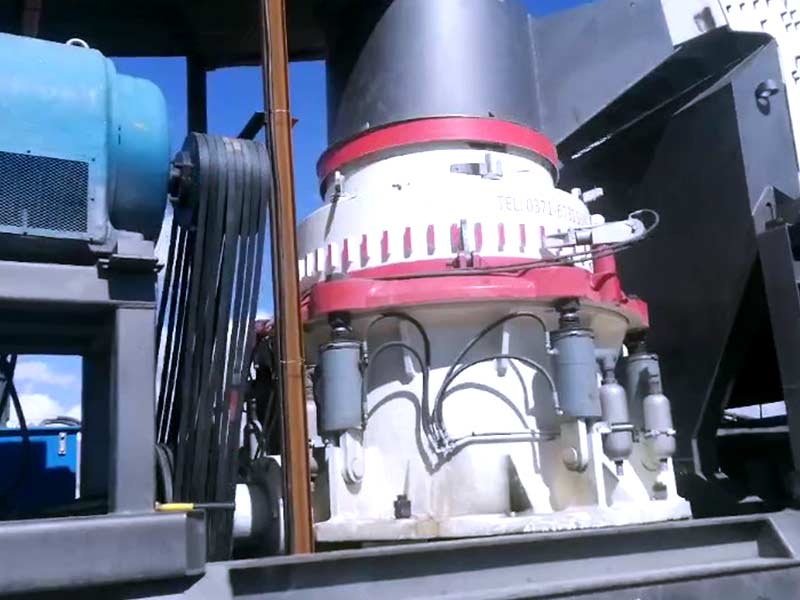

The fully hydraulic cone crusher is composed of an upper frame and a fixed cone, an adjustment ring, a lower frame, a fixed central shaft, a moving cone and a spherical bush, an eccentric sleeve and a sector gear, a pinion and a horizontal shaft, a peripheral hydraulic cylinder, a hydraulic station, a lubrication station, etc. When working, the rotation of the motor drives the pulley or coupling, the transmission shaft and the cone part to make the eccentric shaft perform periodic swing motion below the axis line. After the material enters the crushing chamber from the material inlet, it is crushed by the mutual impact, extrusion, grinding and kneading of the eccentric shaft and the mortar wall. The hydraulic insurance system can remove the faulty objects from the support sleeve and the top of the fixed cone through hydraulic pressure when the machine has an iron fault or a jamming phenomenon. While playing a good insurance role, it greatly reduces the maintenance rate and improves production efficiency.

| Model | Discharging Opening Size(mm) | Capacity(t/h) |

| SHQ300 | 9-38 | 48-168 |

| SHQ400 | 9-51 | 68-308 |

| SHQ500 | 19-65 | 180-575 |

| SHQ600 | 16-64 | 186-640 |

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Price

Get Price