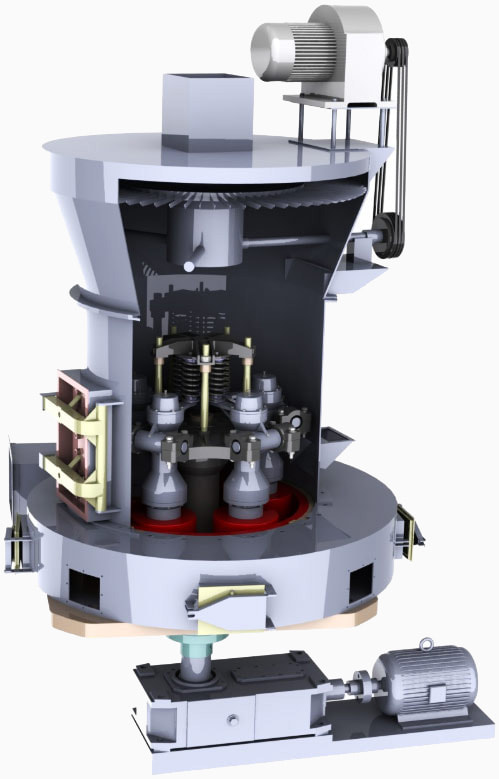

The bevel gear is integrally driven, and the efficiency is significantly improved

The bevel gear is used for the overall transmission, the transmission is stable, the transmission chain is reduced, the transmission ratio is accurate, and the energy loss is sharply reduced; the structure is compact, the installation and adjustment are convenient and fast, and the efficiency is significantly improved.

The three transmission parts are lubricated with thin oil

The main engine, fan and powder separator are lubricated with thin oil, without adding oil pump or lubricating station, the main shaft bearing and bevel gear shaft bearing can be lubricated.

Adopt frequency conversion powder separator to improve the efficiency of powder selection and powder collection

The frequency conversion type powder separator has high motor efficiency and energy saving, F-class insulation, and the protection level is IP54; the isolation structure is adopted between the inner cylinder of the powder separator and the mixed gas powder flow, which effectively improves the powder selection efficiency and powder selection accuracy.

Adopt start-up control technology to ensure reliable operation of equipment

The control cabinet uses a soft starter to start the fan and the main engine, making it easier to start and more reliable to run; intelligent digital technology is used to protect the main engine overcurrent: the intelligent instrument collects the main engine current through the transformer to ensure the smooth operation of the equipment.

The curved surface can change the blade blade, improve the material utilization rate

The blade part is made of high wear-resistant alloy material, and only the blade part needs to be replaced, which improves the material utilization rate; the curved blade can guide the material inside, which increases the effective working area and thus increases the output.

Unique air self-circulation system, energy saving and environmental protection

The unique air self-circulation system has less dust discharge. The production line can be equipped with a pulse dust collector, which has high dust removal efficiency and low emission concentration, and basically realizes the dust-free operation of the workshop.

Language

Language

Email:sales@shibochina.com

Email:sales@shibochina.com

Chat Online

Chat Online Get Price

Get Price