20-30mm、10-20mm、5-10mm、0-5mm

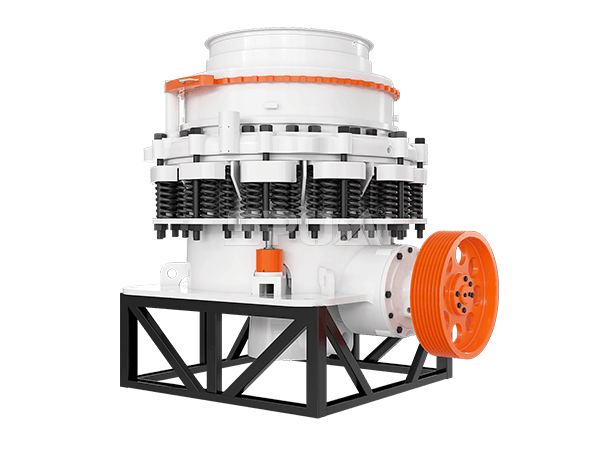

It can crush more than 100 kinds of rocks. The common discharge size is...

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

A variety of cavity types are available for a wide range of applications

A variety of cavity types are available for a wide range of applications

High yield and uniform grain shape

High yield and uniform grain shape

Using spring safety device, overload protection is stable and reliable

Using spring safety device, overload protection is stable and reliable

The discharge port is adjusted by the hydraulic push cylinder, which is easy to adjust

The discharge port is adjusted by the hydraulic push cylinder, which is easy to adjust

In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the drive, and the moving cone is rotating and swinging under the forced motion of the eccentric shaft. The moving cone is close to the section of the static cone and becomes the crushing chamber. The material is broken by the multiple extrusion and impact of the moving cone and the static cone. When the moving cone is away from the section, it has been crushed to the required size, and the material is falling under its own gravity and discharged from the cone bottom.

| Model | Discharging Opening Size(mm) | Capacity(t/h) |

| CS75 | 9-38 | 45-163 |

| CS110 | 9-51 | 63-308 |

| CS160 | 13-51 | 109-349 |

| CS220 | 19-65 | 180-570 |

| CS250 | 16-64 | 181-635 |

| CS315 | 19-64 | 281-1270 |

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Quote

Get Quote