20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

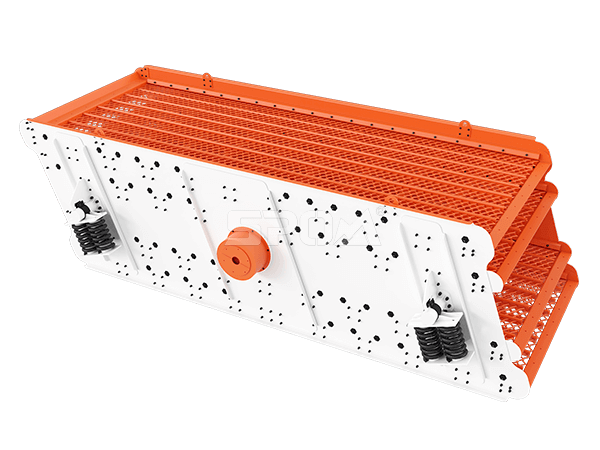

Advanced structure

Advanced structure

Strong exciting force

Strong exciting force

Low vibration and noise

Low vibration and noise

Easy to repair

Easy to repair

The stone is evenly sent to the jaw crusher by the vibrating feeder for coarse crushing, the coarsely crushed material is sent to the fine jaw crusher for re-crushing, and the crushed material is sent to the vibrating screen by the belt conveyor for screening. The stone sand machine that meets the feeding granularity of the sand making machine is used for sand making, and those that do not meet the requirements are returned to the fine jaw crusher for re-crushing, and the materials from the sand making machine are returned to the vibrating screen for re-screening. The separated sand that meets the requirements enters the sand washing machine for cleaning. After cleaning, the finished product is conveyed by the finished product conveyor belt. The sand and gravel mixture that does not meet the requirements is sent to the sand making machine for re-crushing. The production line will eventually form a 2-break closed circuit. Cycle, according to the user's needs can also carry out a variety of configurations.

| Model | Feeding Size(mm) | Capacity(t/h) |

| 2YZK1237 | ≤400 | 30-100 |

| 3YZK1237 | ≤400 | 30-100 |

| 2YZK1548 | ≤400 | 30-275 |

| 3YZK1548 | ≤400 | 30-275 |

| 2YZK1848 | ≤400 | 56-330 |

| 3YZK1848 | ≤400 | 56-330 |

| 4YZK1848 | ≤400 | 56-330 |

| 2YZK1860 | ≤400 | 65-586 |

| 3YZK1860 | ≤400 | 65-586 |

| 4YZK1860 | ≤400 | 65-586 |

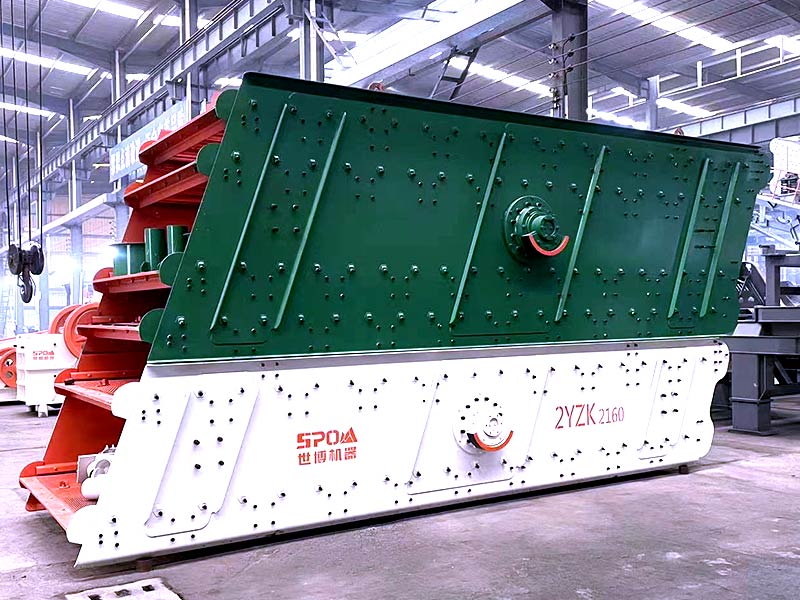

| 2YZK2160 | ≤400 | 81-720 |

| 3YZK2160 | ≤400 | 81-720 |

| 4YZK2160 | ≤400 | 81-720 |

| 2YZK2460 | ≤400 | 100-810 |

| 3YZK2460 | ≤400 | 100-810 |

| 4YZK2460 | ≤400 | 150-850 |

| 2YZK2870 | ≤400 | 120-680 |

| 3YZK2870 | ≤400 | 180-720 |

| 2YZK3070 | ≤400 | 200-700 |

| 3YZK3070 | ≤400 | 230-800 |

SPOM specializes in the manufacture of aggregate aggregate solutions, grinding equipment and mobile stations. Customers are located in more than 120 countries and regions around the world.

Chat Online

Chat Online

Get Price

Get Price